While the case studies are actual, the names and locations have been changed to protect the identity of clients.

Background

Thakur Farms, a climate-controlled hydroponic farm in Jaipur, faces summer temperatures of up to 47°C. To manage this, they installed various cooling systems, including fan-and-pad, fogging, and water chilling, all manually operated by staff. Traditionally, the cooling was turned on in the morning and off in the evening, with intermittent fogging as needed.

Issue

- High electricity bill, impacting farm profitability.

- Human errors resulting in temperature spikes, causing bolting in sensitive crops.

Solution

We introduced an IoT-enabled, rule-based system to synchronize equipment operation, featuring:

- Grouping exhaust fans into two subsets.

- Activating exhaust fan subsets by temperature threshold.

- Controlling the cooling pad system by temperature and time-based interval cut-off.

- Linking chilling pad system activation to temperature.

- Activating the fogging system based on humidity and temperature thresholds, with timed intervals.

- Managing air circulation fans by temperature with timed cut-offs.

- Prioritizing operations of all systems through a rule engine.

Result

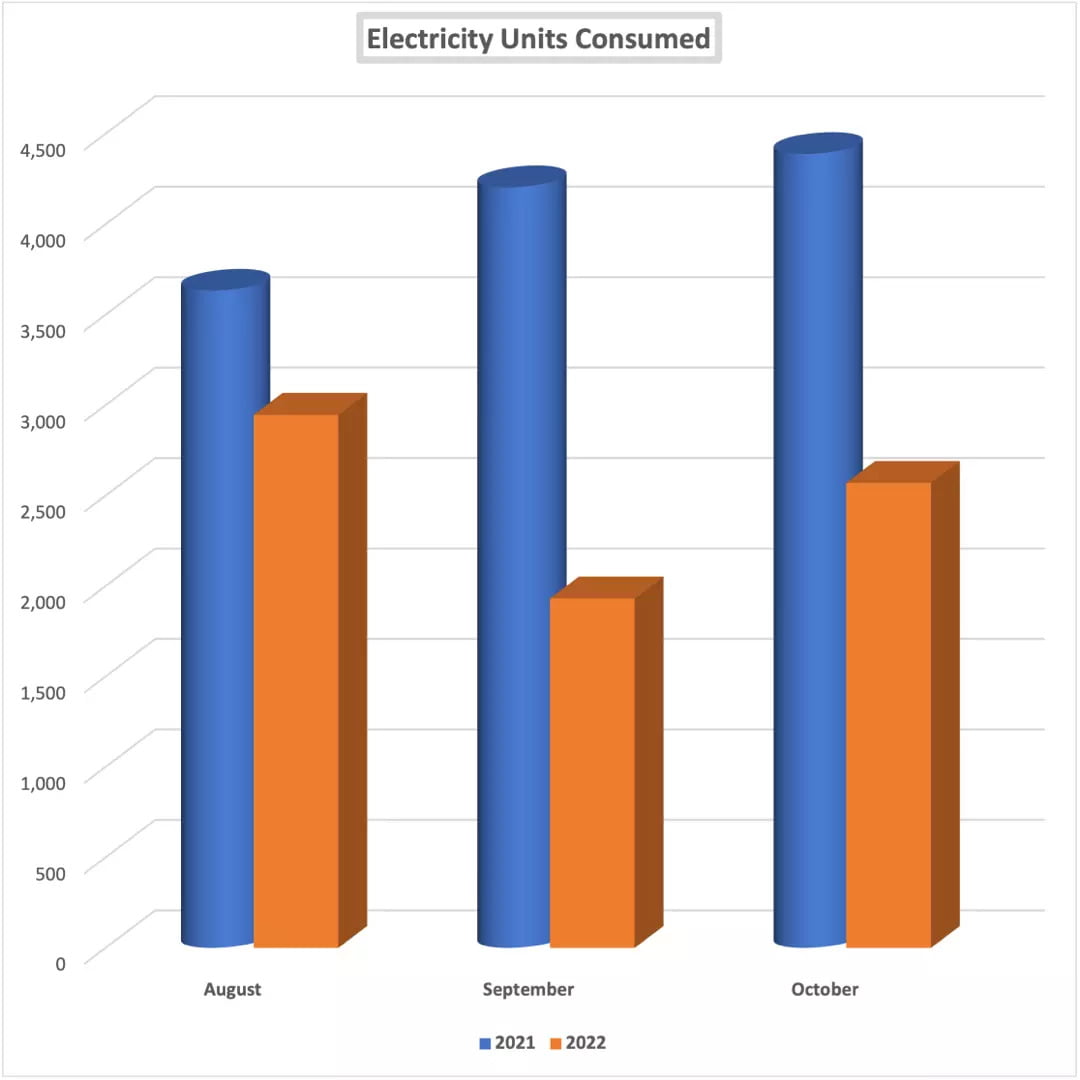

39% reduction in electricity consumption.

Evidence

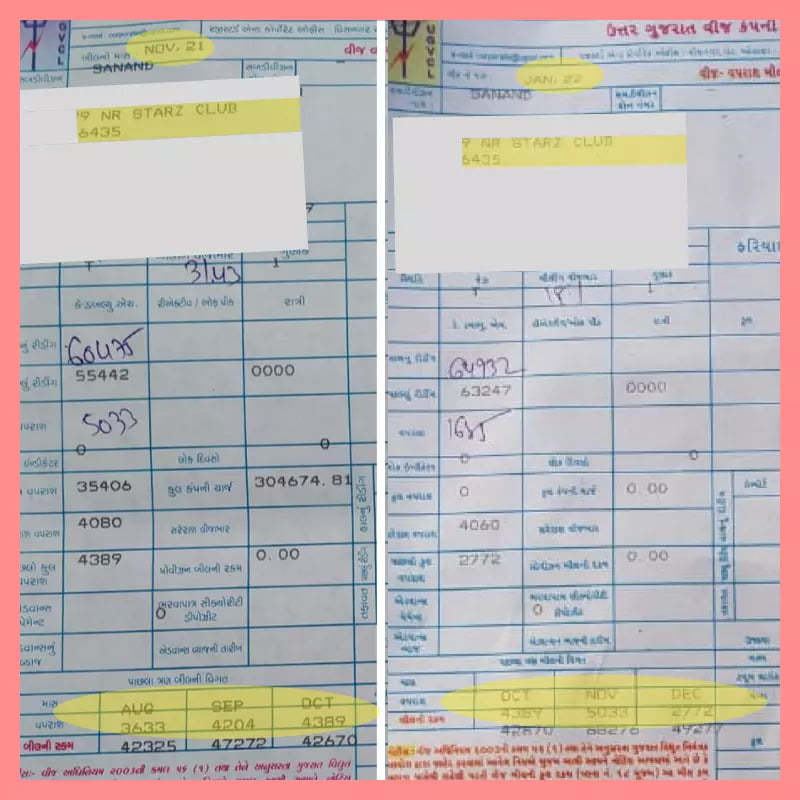

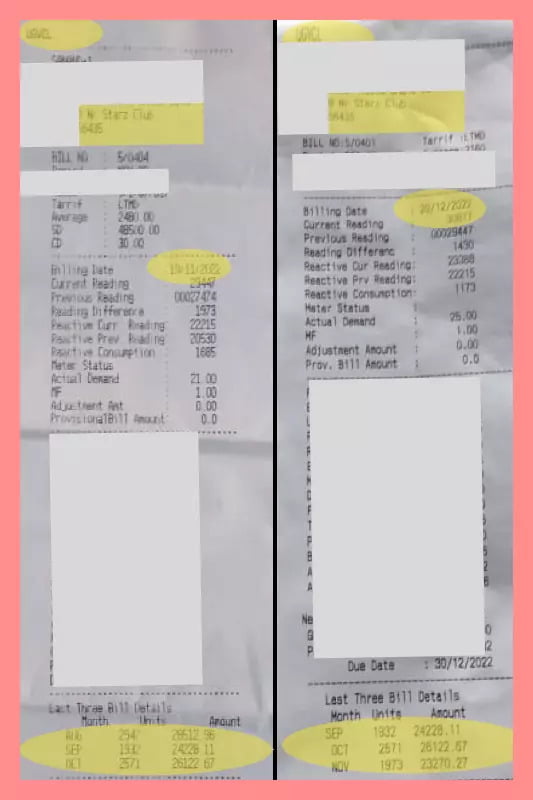

Total units consumed during Aug, Sep, Oct 2021 - 12,226

Total units consumed during Aug, Sep, Oct 2022 - 7,450